(a) dimensions of heavy series nuts inch metrics

Dimension

Nuts shall comply with the dimension and tolerances given in table 22 or 23.

Note: Nuts of the followinggrades(see table 4) should be supplied as heavy series (see table

22)

unless the purchaser requests the normal series: 2H 4 L4 7 8C

8T

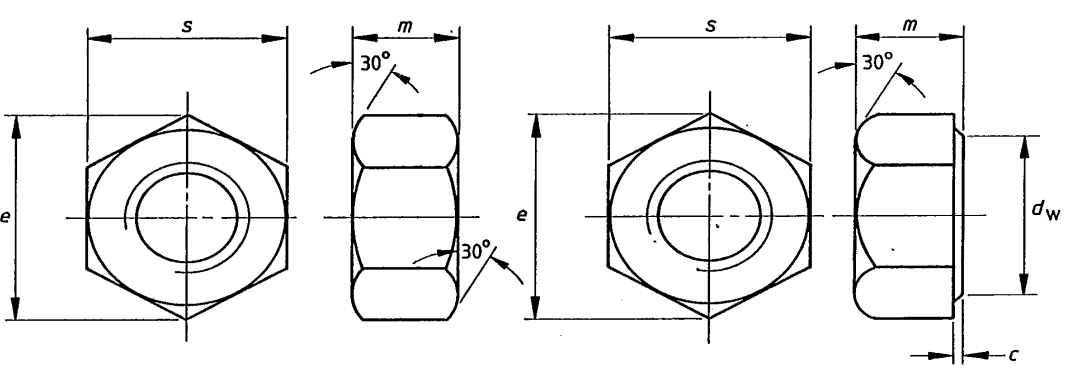

Heavy series nuts (see table 22) and normal series nuts (see table 23) shall have a chamfer of

approximately 30° on the non-bearing face.

The bearing face shall be finished with either a washer face or a chamfer of approximately

30°.

The bearing face shall be machined or have a surface finish equal to that produced by

machining.

The face of the nut hsall be square to the axis of the thread of the nut within the tolerances

given in table 22 and 23(see figure 6 and 7) when tested as described in appendix E.

Screw threads shall be ISO inch (UNC) for sizes up to and including 1 in diameter and 8

threads/in (8 UN series) for sizes 1 1⁄8 in diameter and above in accordance with BS 1580 and

shall

conform to the tolerances for class 2B specified in that standard.

NOTE. See Item (d) (6) of appendix C.

The screw threads of nuts shall be concentric with the hexagon within a tolerance of 2 IT13,

FIM, using the width across the flats as the reference datum.

| Dimensions of heavy series nuts: inch series | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal size | Threads Per inch | Width across flats 𝑠 | Width across corners 𝓮 max. | Washer face | Thickness 𝑚 | Tolerance on sequencess | ||||||||

| max. | min. | Diameter d𝑤 | Thickness 𝑐 | |||||||||||

| max. | min. | max. | min. | |||||||||||

| in | thread/in | in | in | in | in | in | in | in | in | in | ||||

| ½ | 13 | 0.875 | 0.85 | 1.01 | 0.836 | 0.808 | 1/64 | 0.504 | 0.464 | 0.015 | ||||

| ⅝ | 11 | 1.062 | 1.031 | 1.23 | 1.013 | 0.979 | 1/64 | 0.631 | 0.587 | 0.016 | ||||

| ¾ | 10 | 1.250 | 1.212 | 1.44 | 1.189 | 1.150 | 1/64 | 0.758 | 0.710 | 0.019 | ||||

| ⅞ | 9 | 1.438 | 1.394 | 1.66 | 1.366 | 1.324 | 1/64 | 0.885 | 0.833 | 0.023 | ||||

| 1 | 8 | 1.625 | 1.575 | 1.88 | 1.539 | 1.496 | 1/64 | 1.012 | 0.956 | 0.023 | ||||

| 1⅛ | 8 | 1.812 | 1.756 | 2.09 | 1.710 | 1.668 | 1/64 | 1.139 | 1.079 | 0.027 | ||||

| 1¼ | 8 | 2.000 | 1.938 | 2.31 | 1.892 | 1.841 | 1/64 | 1.251 | 1.187 | 0.027 | ||||

| 1⅜ | 8 | 2.188 | 2.119 | 2.53 | 2.070 | 2.013 | 1/64 | 1.378 | 1.310 | 0.030 | ||||

| 1½ | 8 | 2.375 | 2.3 | 2.74 | 2.251 | 2.185 | 1/64 | 1.505 | 1.433 | 0.030 | ||||

| 1⅝ | 8 | 2.562 | 2.481 | 2.96 | 2.433 | 2.857 | 1/64 | 1.632 | 1.556 | 0.030 | ||||

| 1¾ | 8 | 2.750 | 2.662 | 3.18 | 2.605 | 2.529 | 1/64 | 1.759 | 1.679 | 0.030 | ||||

| 1⅞ | 8 | 2.938 | 2.844 | 3.39 | 2.779 | 2.702 | 1/64 | 1.886 | 1.802 | 0.035 | ||||

| 2 | 8 | 3.125 | 3.025 | 3.61 | 2.949 | 2.874 | 1/64 | 2.013 | 1.925 | 0.035 | ||||

| 2¼ | 8 | 3.500 | 3.388 | 4.04 | 3.296 | 3.219 | 1/32 | 2.251 | 2.155 | 0.040 | ||||

| 2½ | 8 | 3.875 | 3.75 | 4.47 | 3.65 | 3.563 | 1/32 | 2.505 | 2.401 | 0.045 | ||||

| 2¾ | 8 | 4.250 | 4.112 | 4.91 | 4.012 | 3.906 | 1/32 | 2.759 | 2.647 | 0.050 | ||||

| 3 | 8 | 4.625 | 4.475 | 5.34 | 4.373 | 4.251 | 1/32 | 3.013 | 3.893 | 0.055 | ||||

| 3½ | 8 | 5.375 | 5.2 | 6.21 | 5.061 | 4.94 | 1/32 | 3.506 | 3.370 | 0.060 | ||||

| 3¾ | 8 | 5.750 | 5.2 | 6.21 | 5.061 | 4.94 | 1/32 | 3.506 | 3.370 | 0.065 | ||||

| 4 | 8 | 6.15 | 5.925 | 7.07 | 5.78 | 5.62 | 1/32 | 4.014 | 3.862 | 0.070 | ||||